The Rhomberg PBG gauge is for heavy duty service where vibration or pulsation of medium would cause excessive wear on a dry gauge or where corrosive ambient conditions prevail. Specific application examples are:

The Rhomberg PBG gauge is for heavy duty service where vibration or pulsation of medium would cause excessive wear on a dry gauge or where corrosive ambient conditions prevail. Specific application examples are:

Hydraulic equipment

Mining equipment

Irrigation equipment

PBG Features

| Window | Extruded acrylic sheet |

| Seal | Neoprene |

| Case & Bezel | 304 stainless steel |

| Dampening Fluid | Glycerine, silicon [options available] |

|

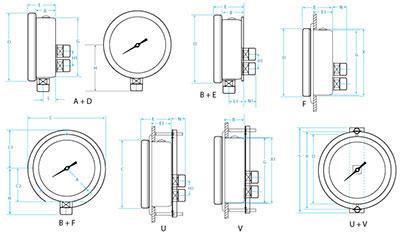

A B D E F U V

[52mm available only D configuration]

|

|

| Nominal Sizes |

mm 52 63 100

Imp 2" 2½" 4"

|

| Socket | Brass or stainlees steel |

| Bourdon tube | Bronze or stainless steel |

| Movement | brass or stainless steel |

| Dial | Aluminium, white with black numerals |

| Pointer | aluminium, black anodised |

| Connections |

1/8" + 1/4" [BSP - NPT - BSPT] Options 3/8" + 1/2"

[bottom and centre-back]

|

| Maximum Range | 60Mpa [brass] 100 Mpa [Stainless steel] |

| Accuracy | 1.6%FSD |

| Temperature Range |

Ambient temperature: -25°C to 60°C

Note: minimum temperature should not be less or equal to the freezing point of the process fluid.

Higher temperatures can be accommodated with heat reducing devices.

|

PBG Pressure Gauge Configuration

PBG Pressure Gauge

| Normal Size | Dimensions [X is panel cut-out diamter] | ||||||||||||||||||||

|

Metric

Imperial

|

A | B | C | C1 | C2 | D | E | E1 | E3 | E4 | G | H | H1 | L | L1 | N | N1 | O | R | S | X1 |

|

63mm

2.5"

|

37,00

1,48

|

22,00

0,87

|

85,00

3,35

|

42,50

1,67

|

36,50

1,44

|

69,00

2,72

|

29,00

1,14

|

33,00

1,30

|

22,00

0,87

|

25,50

1,01

|

62,00

2,44

|

60,00

2,36

|

16,50

0,55

|

9,00

0,35

|

13,00

0,51

|

27,00

1,05

|

23,00

0,91

|

3,50

0,14

|

66,00

2,68

|

77,00

3,03

|

63,50

2,50

|

|

100mm

4"

|

58,00

2,28

|

22,00

0,87

|

133,00

5,24

|

66,50

2,62

|

58,00

2,20

|

108,50

4,27

|

29,00

1,14

|

34,00

1,34

|

22,00

0,87

|

24,00

0,95

|

99,50

3,05

|

77,50

3,39

|

9,00

0,35

|

13,50

0,93

|

23,50

0,93

|

23,50

0,93

|

5,00

0,20

|

110,00

4,33

|

122,00

4,48

|

101,00

3,98

|

|