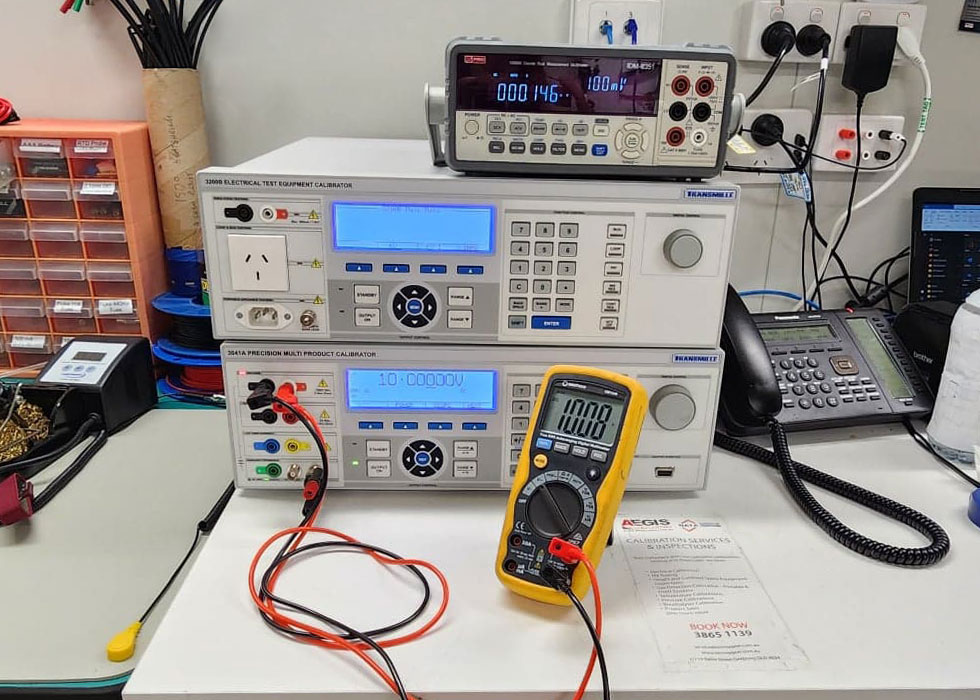

Electrical Equipment Calibration & Testing

Aegis Sales & Service provide calibration, testing, and inspection services for your specialised electronic equipment.

Australian Standards AS/NZS 3017 and AS/NZS3019 suggest that testing instruments should be calibrated at appropriate intervals.

Many equipment manufacturers specify calibration of their equipment is carried out every 12 months when used in a laboratory environment or shorter periods when used in a harsh environment. Harsh environments can include extreme temperatures, construction sites, and even how the equipment is stored ie: most trades peoples' utes/vans/trailers could be considered a harsh environment as the equipment can be tossed in the back or thrown around building sites, left outside or not used in the recommended operating temperature range. For these reasons, we recommend 6-monthly calibrations rather than 12 monthly which the manufacturers recommend when used in optimum conditions.

We can help you make sure that your electrical equipment is performing and reporting accurate test results with regular calibration of all types of electrical equipment, including:

- Multimeter calibration

- Clamp meter calibration

- Insulation tester calibration

- Multifunction/installation tester calibration

- PAT Tester Calibration

- Process meters

- RCD testers

- Loop testers

- Industrial thermal imaging

- Personal IR thermometers

HV Testing

Testing your High Voltage Equipment is important to ensure that all equipment is fit for use and will protect you when working with live electricity.

At Aegis Sales & Service we can test the following High Voltage (HV) equipment:

- Insulated gloves

- Insulated mats

- LV Rescue kits

- HV Rescue kits

- Hot sticks/fuse pullers

- Tiger tails

- Insulated tools

Electrical Equipment Calibration & Testing

We recommend electrical equipment calibration and testing every six months.