The PBB gauge range features a welded construction with back blow out disc.

The PBB gauge range features a welded construction with back blow out disc.

This Rhomberg gauge is ideally suited to most industrial applications where high accuracy and durability is a must.

Gauges are available with either brass / bronze internals, all stainless steel internals or Monel Bourdon tube and socket with stainless steel movement.

All guages are retro-fillable and totally repairable. A number of optional accessories are available either as factory fitted or retro-fitted. A Rhomberg vibration free movement [VFM] can be fitted where filling material is not allowed or excessive vibration is present.

The high impact movement [conforming to military specifications]protects against entanglement of the hairspring in the pinion and segment - the most common cause of gauge failure.

PBB Pressure Gauge Specifications

| Window | Acrylic as standard [safety glass optional] |

| Seal | Nitrile [natural rubber for silcon fills |

| Case & Bezel | Brush finish 304 stainless steel |

| Dampening Fluid | Glycerine, silicon or halocarbon [for oxidising services] |

| Blow out Disc | Material: TPV |

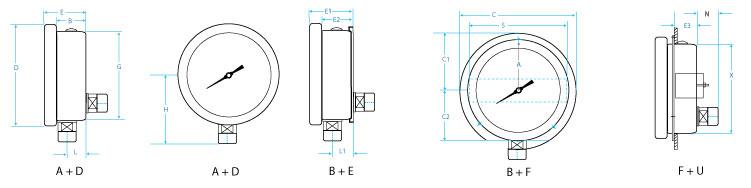

| Configuration | A B D E F U V |

| Mountings |

Direct, surface or panel mounting

mm 63 100 150 250

Imp 2½" 4" 6" 10"

|

| Socket & Bourdon Tube |

Code: Socket: Bourdon Tube:

SS 316/Ti 316Ti

BB brass bronze

MM Monel 400 K-Monel

|

| Movement |

Code:

SS / MM 300 seires stainless steel high impact movement

BB brass / nickel silver high impact movement

|

| Dial | Aluminium, black lettering on white background |

| Pointer | Black aluminium, micrometer adjustable |

| Connections | 1/4" + 3/8" + 1/2" [NPT - BSP] other connections available on request |

| Maximum Range | Vacuum through 100 MPa. Higher ranges available on request |

| Snubbing | Snubbing / throttle screws available in brass and stainless steel |

| Accuracy |

100mm & 150mm 1.0%FSD [SABS 1062]

63mm 1.6%FSD

|

| Temperature Range |

Ambient temperature: -25°C to 60°C

Note: minimum temperature should not be less or equal to the freezing point of the process fluid. Higher temperatures can be accommodated with heat reducing devices.

|

| Approvals | SABS 1062 [1985 for 100mm and 150mm] |

| Nett Mass | 63mm 100mmm 150mm 250mm

Dry 155g 556g 850g 1789g

Filled 230g 816g 1750g 2690g

|

PBB Pressure Gauge Configuration

PBB Pressure Gauge Dimensions

| Normal Size | Dimensions [X is panel cut-out diamter] | |||||||

|

Metric

Imperial

|

B | C | C1 | C2 | D | E | E1 | E2 |

|

63mm

2.5"

|

22,70

0,89

|

85,00

3,35

|

42,50

1,67

|

36,00

1,42

|

69,60

2,74

|

32,50

1,28

|

32,50

1,41

|

27,20

1,07

|

|

100mm

4"

|

38,85

1,54

|

133,00

5,24

|

66,50

2,62

|

58,50

2,22

|

108,00

4,43

|

47,65

2,17

|

57,50

2,26

|

38,55

1,64

|

|

150mm

6"

|

29,00

1,14

|

196,00

7,72

|

96,00

3,85

|

58,50

2,22

|

108,00

4,43

|

47,65

2,17

|

57,50

2,26

|

38,55

1,64

|

|

250mm

9.8"

|

34

1,3

|

285

11,2

|

N/A

N/A

|

N/A

N/A

|

250

9,8

|

56

2,2

|

58

2,3

|

36

1,4

|

| Normal Size | Dimensions [X is panel cut-out diamter] | ||||||||

|

Metric

Imperial

|

E | G | H | S | L | L1 | N | O | X |

|

63mm

2.5"

|

22,00

0,87

|

62,00

2,44

|

60,00

2,36

|

66,50

2,62

|

9,00

0,35

|

13,00

0,51

|

27,00

0,51

|

3,50

0,14

|

63,50

2,50

|

|

100mm

4"

|

29,70

1,17

|

99,00

3,90

|

92,60

3,39

|

106,00

4,17

|

16,50

7,4

|

21,90

8,6

|

38,00

1,49

|

4,80

1,9

|

101,00

3,98

|

|

150mm

6"

|

29,70

1,17

|

99,00

3,90

|

92,60

3,39

|

105,00

4,17

|

16,50

7,4

|

21,90

8,6

|

38,00

1,49

|

45,80

0,23

|

142,00

5,60

|

|

250mm

9.8"

|

51

2

|

248

9,8

|

156

6,1

|

N/A

N/A

|

19

0,7

|

22

0,9

|

41

1,6

|

N/A

N/A

|

253

10,1

|